- Slurry Pump

- NZJA Heavy Slurry Pump

- NZJL Light Slurry Pump

- NZJF Foam Slurry Pump

- NZJV Vertical Double Suction Slurry Pump

- NZJH Centrifugal Slurry Pump

- Grinding Mill Spare Parts

- Mill Rubber Liners

- Rubber Discharge End

- Rubber End Plate

- Mill Rubber Panel

- Feeding Inlet Rubber Liner

- Rubber Pulp Lifters

- Composite Mill Liners

- Composite Lifter Bars

- Composite Mill Trunnion Liner

- Rubber Trommel Screen

- Reverse Spiral Trommel Screen

- Cylindrical Trommel Screen

- Quality Classification Trommel Screen

- Rubber Conical Trommel Screen

- Vibrating Screen Panels

- Rubber Sieve Panel

- Composite Pipe for Mine

- Mining Rubber Hose

- Steel and Rubber Composite Pipe

- Flotation Machine Spare Parts

- Flotation Machine Rotors and Stators

- Hydrocyclone

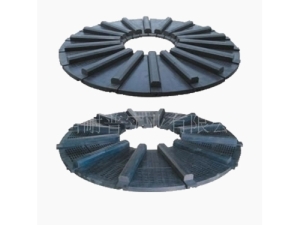

Feeding Inlet Rubber Liner

Introduction

Rubber mill liner is a useful spare part for grinding machines, which can prevent friction and improve grinding efficiency. It is chiefly made up of a metal framework and wearproof rubber. Feeding inlet rubber liner is characterized by simple structure, stable performance, reasonable structure and easy installation.

Advantages

1. Rubber mill liner can reduce energy consumption and absorb noise and vibration. It is environmentally-friendly and economical.

2. The feeding inlet rubber liner is durable and can be used twice as long as metal ones.

3. The rubber is elastic and stable, thus anti-corrosive. And it has small density.

4. Rubber mill liner is easy to change and maintain.

5. Its working process is under strict supervision, thus reliable.

rubber liners for mills.pdf

Packaging and Shipping

1. Rubber mill liner should be packaged in iron cases.

2. Shipping ways are by sea and land transportation.

Payment and Delivery Time of Feeding Inlet Rubber Liner

1. Types of payment: L/C and T/T.

2. Delivery time: 30 to 60 days after receiving down payment.

After-sale Service

Field installation and maintenance services can be offered providing the purchase orders of rubber mill liner reach a certain amount.

As an experienced manufacturer, Naipu Company now makes slurry pump, mill spare parts (rubber mill liner), vibrating screen panels, composite pipe and hydraocylones. The company has national first-class double vacuum vulcanizing machine and Taiwan testing equipment. We employ imported natural rubber which has performance of high wear resistance and anti corrosion. All these lead to the wide popularity of feeding inlet rubber liner both at home and abroad.

- Rubber Pulp LiftersRubber pulp lifters are necessary for mills, which strengthen grinding effects and improve efficiency. Rubber lifter bars for grinding machine can be used for 36 months, while the metal ones 12 months. Made of rubber material, they are much lighter and anti-corrosion.1. A unique wear-resistant (structure, material) design. 2. Wide range of performances and high performance cost ratio. 3. Stable and durable...